- <

- Top

- About Imatest

- Getting Started

- Image Quality Factors

- Software Releases

- Product Overview

- In the Lab

- Measuring & Reading IQ Plots

- Webinars

- Industry Events

- Standards

- Speeding up videos

Support

Videos

Categories

About Imatest

Imatest Provides third-party, objective image quality testing to meet your needs. If you’re new to testing or unfamiliar with image quality metrics, we’re here to help. Supplement your report with an expert analysis of your results, with specific interpretation of output metrics for your particular device and application. We know that each test lab setup is unique to the needs of your company, and Imatest can cater your test lab service goals.

Getting Started

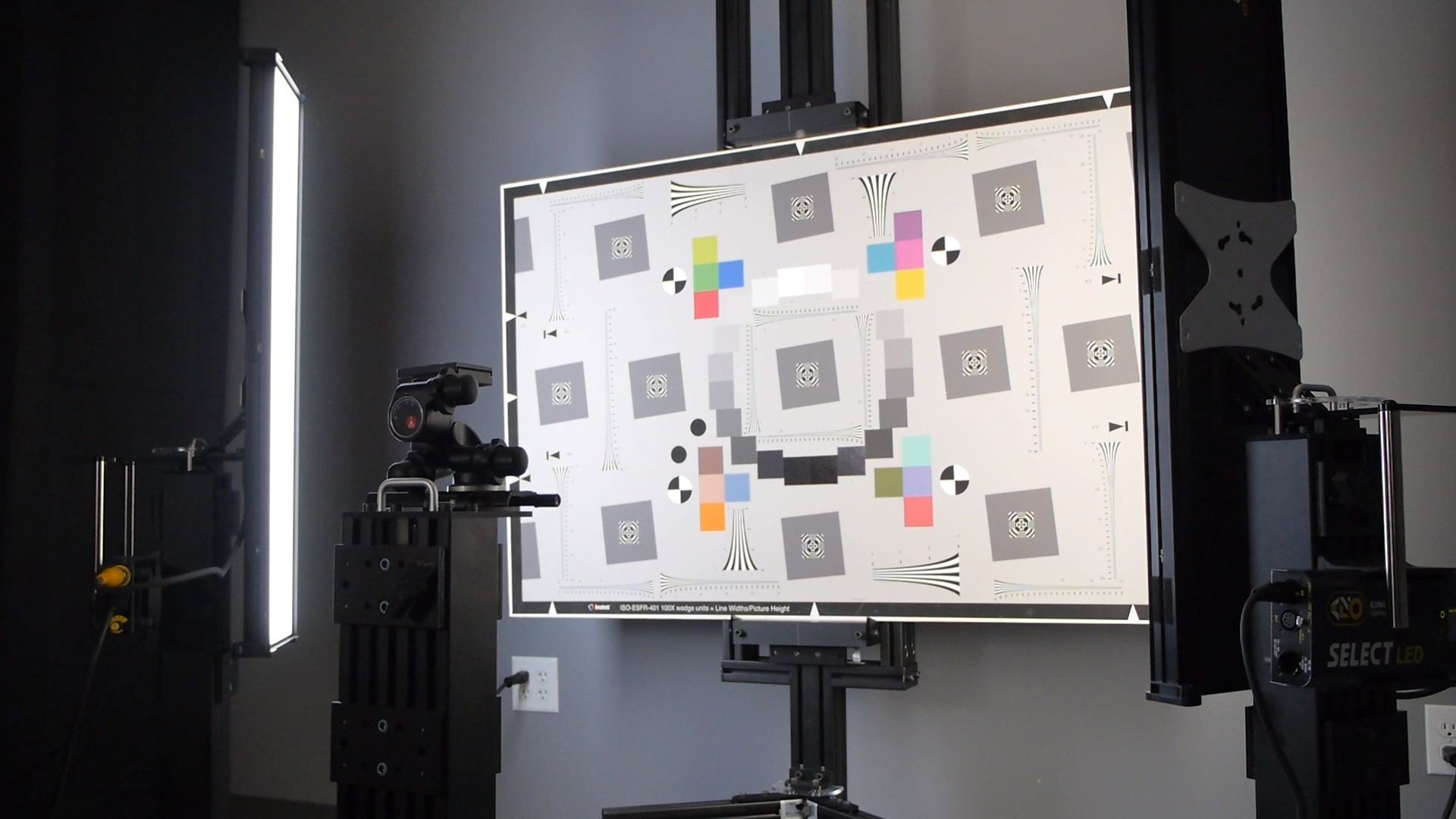

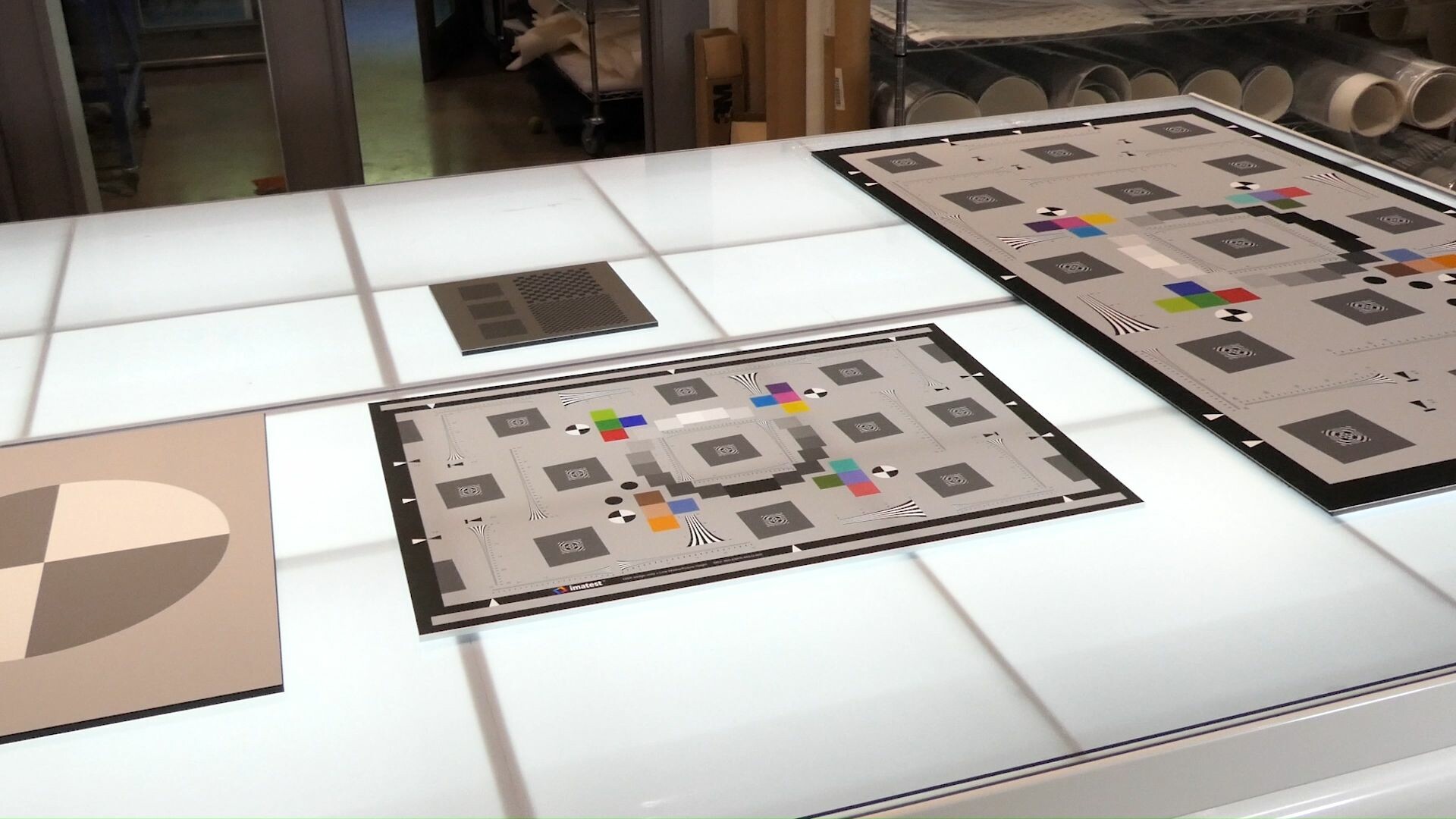

mage quality test charts should be mounted on a smooth flat surface, like an acrylic board, to ensure no blemishes, bends, or bubbles occur that negatively impact image quality measurements. Imatest offers the option to professionally mount our test charts on acrylic or E-panel.

Image Quality Factors

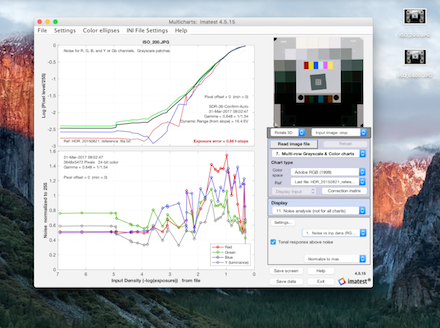

The highest quality images are created by optimizing many key image quality factors. Noise is an undesirable random spatial variation, visible as grain in film, or pixel level fluctuation in digital images. Learn how Noise effects your camera system using Imatest.

Lateral chromatic aberration (LCA), AKA lateral chromatic displacement (LCD) and "color fringing", is a lens aberration that causes colors to focus at different distances from the image center. It is most visible near the corners of images. In this video, we will explain the techniques used to measure for LCA.

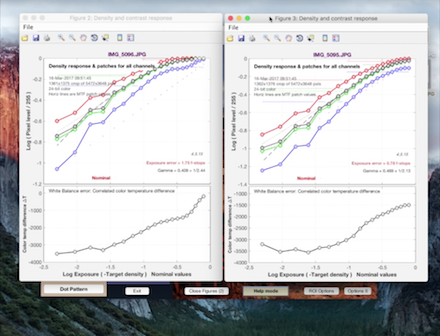

The highest quality images are produced by optimizing many key factors. Dynamic Range is characterized by the ratio between the highest light intensity that a camera system can capture and the darkest tones that become indistinguishable from noise. Dynamic range measurements are useful for optimizing system performance and for verifying camera design specifications. Informed consumers seek camera systems with superior dynamic range, which can capture information in dark shadows while maintaining detail in brighter areas.

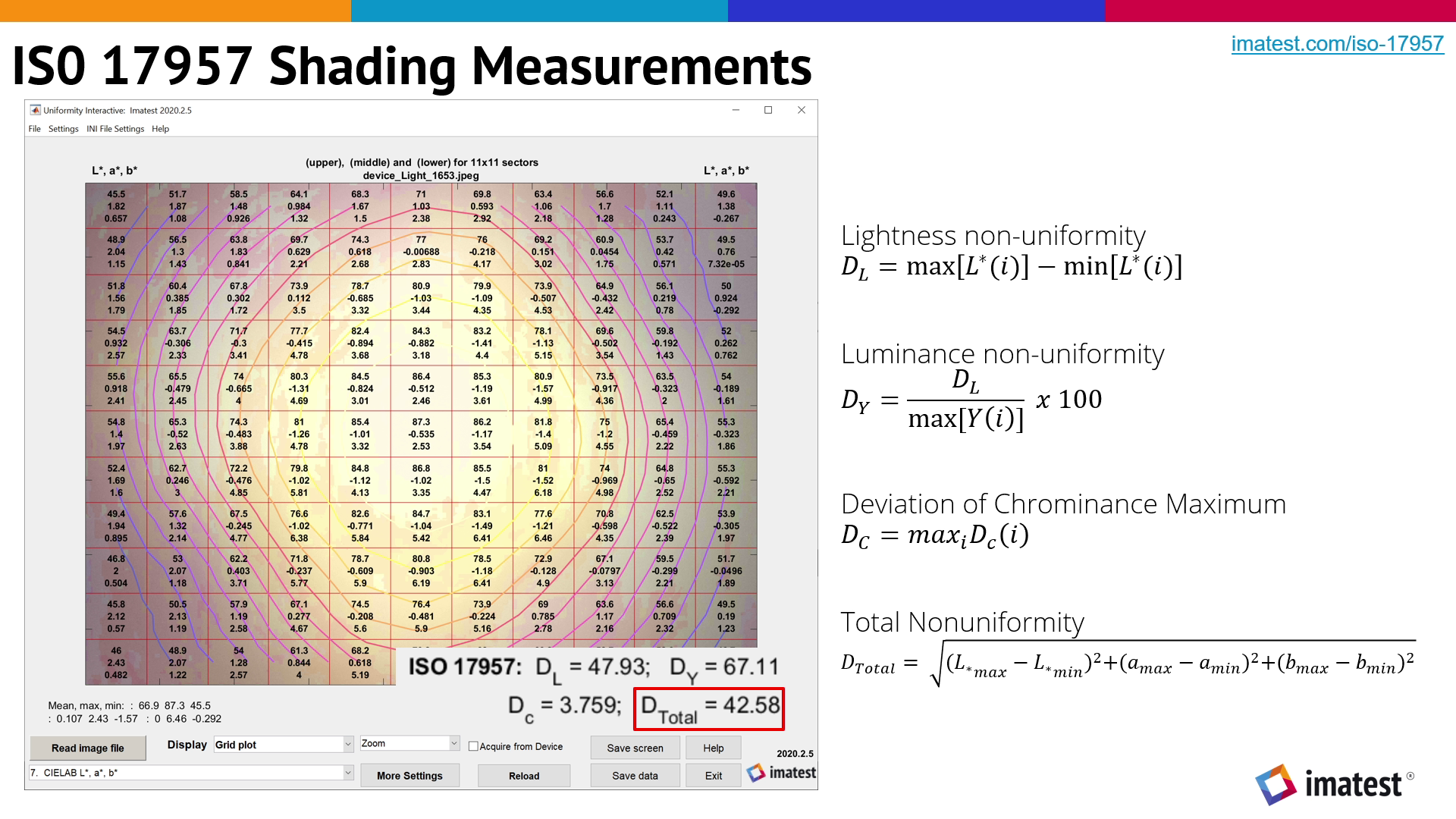

Lens shading, Light falloff & Vignetting: Where your image becomes darker the further you get from the center. This is due to the radial nature of the lens which collects more light in the center. It can be particularly strong with wide angle lenses. Non-uniformity is also caused by the chief ray angle of light incident to the sensor which has reduced quantum efficiency as the angle increases.

Software Releases

Imatest 22.1, released on August 30, 2022, includes Automatic Chart Identification, Internationalization, ISO 12233 Standards Support, Sagittal/Tangential MTF Plot Updates, and more. See www.imatest.com/22-1.

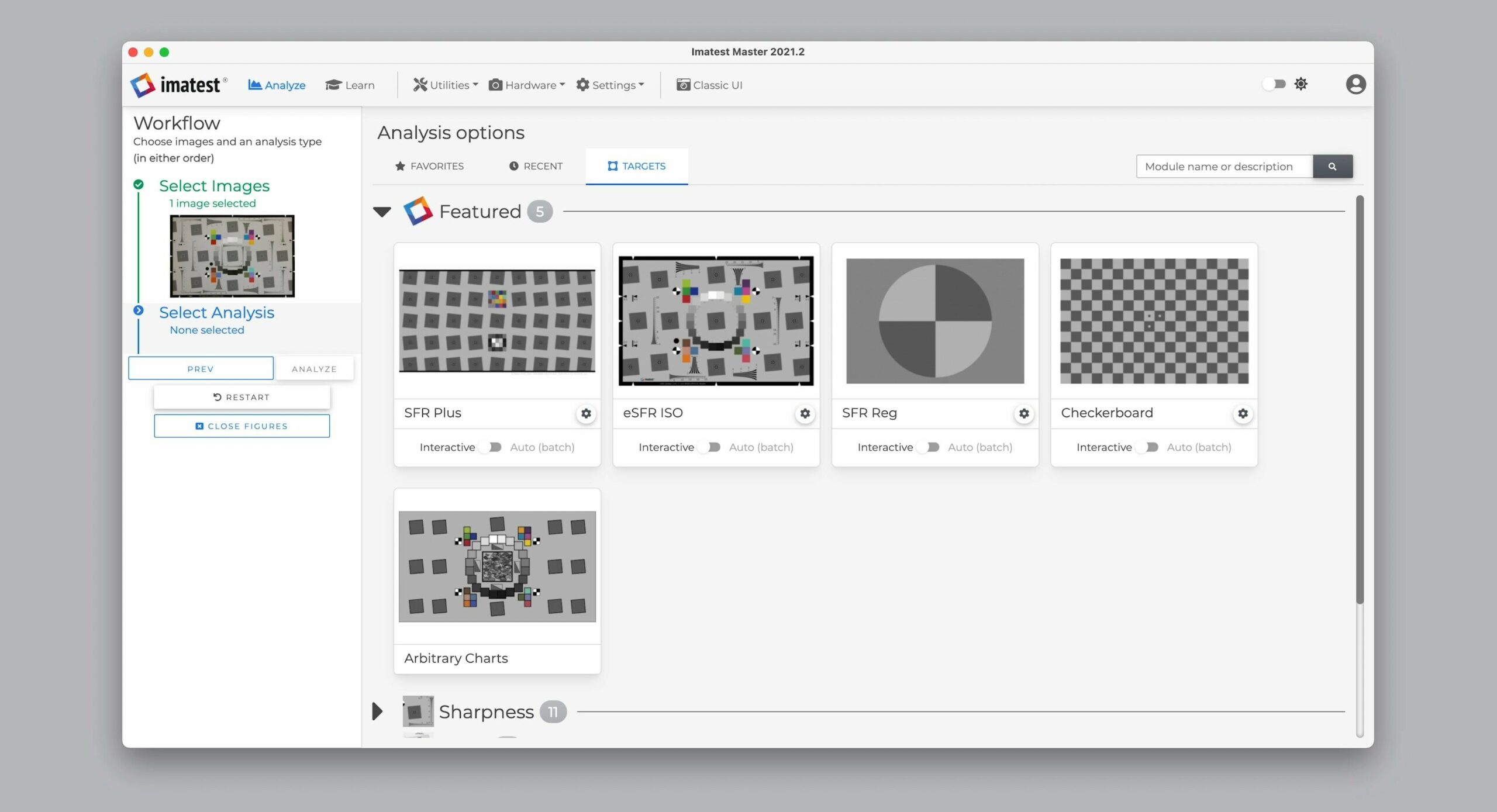

Imatest 2021.2 released November 17, 2021, includes a New Main Window User Interface, File First workflow, Dark Mode, and more. See www.imatest.com/2021.2.

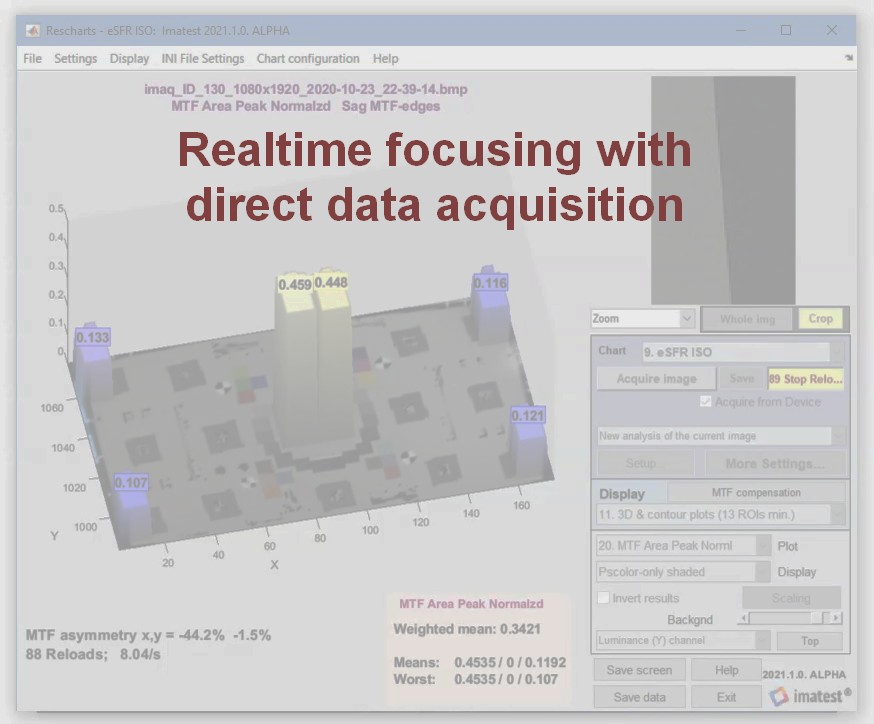

Imatest Master can perform real time analysis of a wide range of camera systems. For more about our latest release, see www.imatest.com/2021.1.

Imatest 5.0 includes groundbreaking additions to expand the capabilities of your image quality testing pipeline. For more information, please visit www.imatest.com/imatest-5-0.

Product Overviews

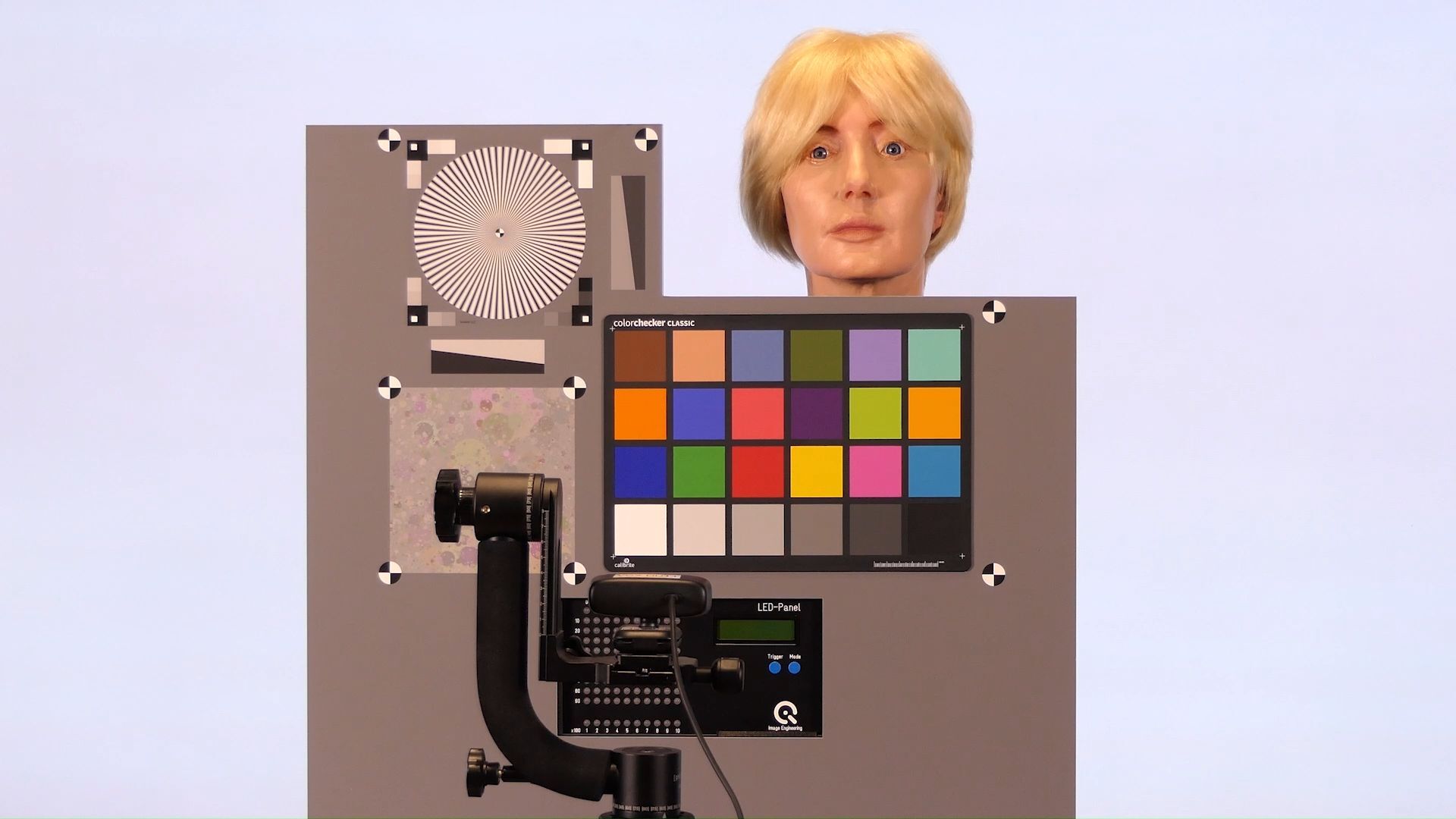

The VCX WebCam Studio is a comprehensive target designed to measure a variety of Image Quality Factors. This target is designed according to VCX Webcam standard specifications. The chart contains the Calibrite Classic ColorChecker, Siemens star, spilled coins/dead leaves texture, and slanted edge targets. The VCX webcam studio optionally includes motorized head turner and two different mannequin heads—one with a dark skin tone (Richard) and a second with a light skin tone (Alexis), which are used to compare the behavior of auto white balance (AWB) and auto exposure (AE) algorithms under various conditions. The rotary head turner can turn the head to look away from the camera for testing of adaptive auto-exposure in video webcams. Optionally includes Camera Timing System LED-Panel for timing testing and/or a Specbos spectraradiometer for measuring the lighting spectrum.

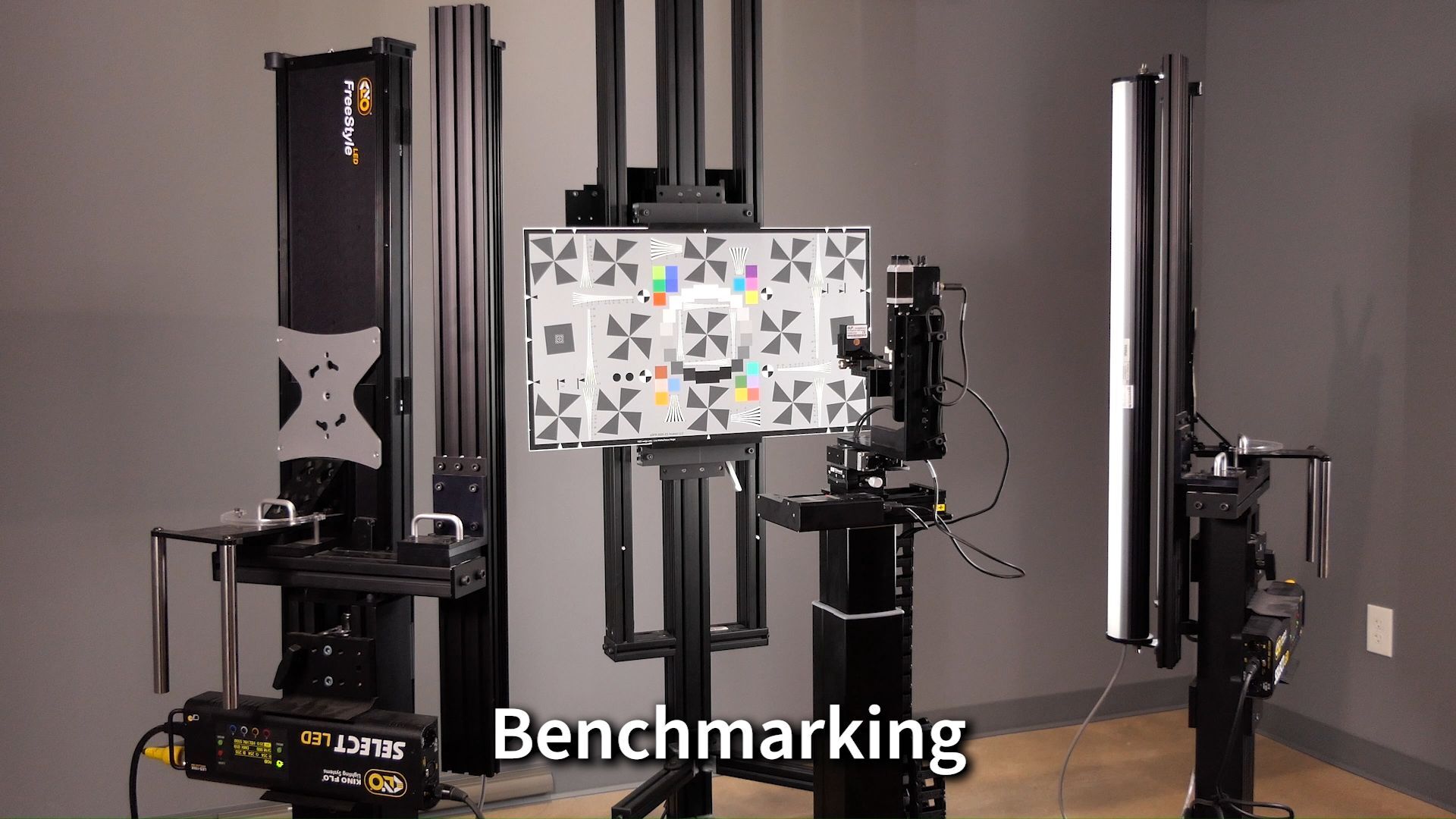

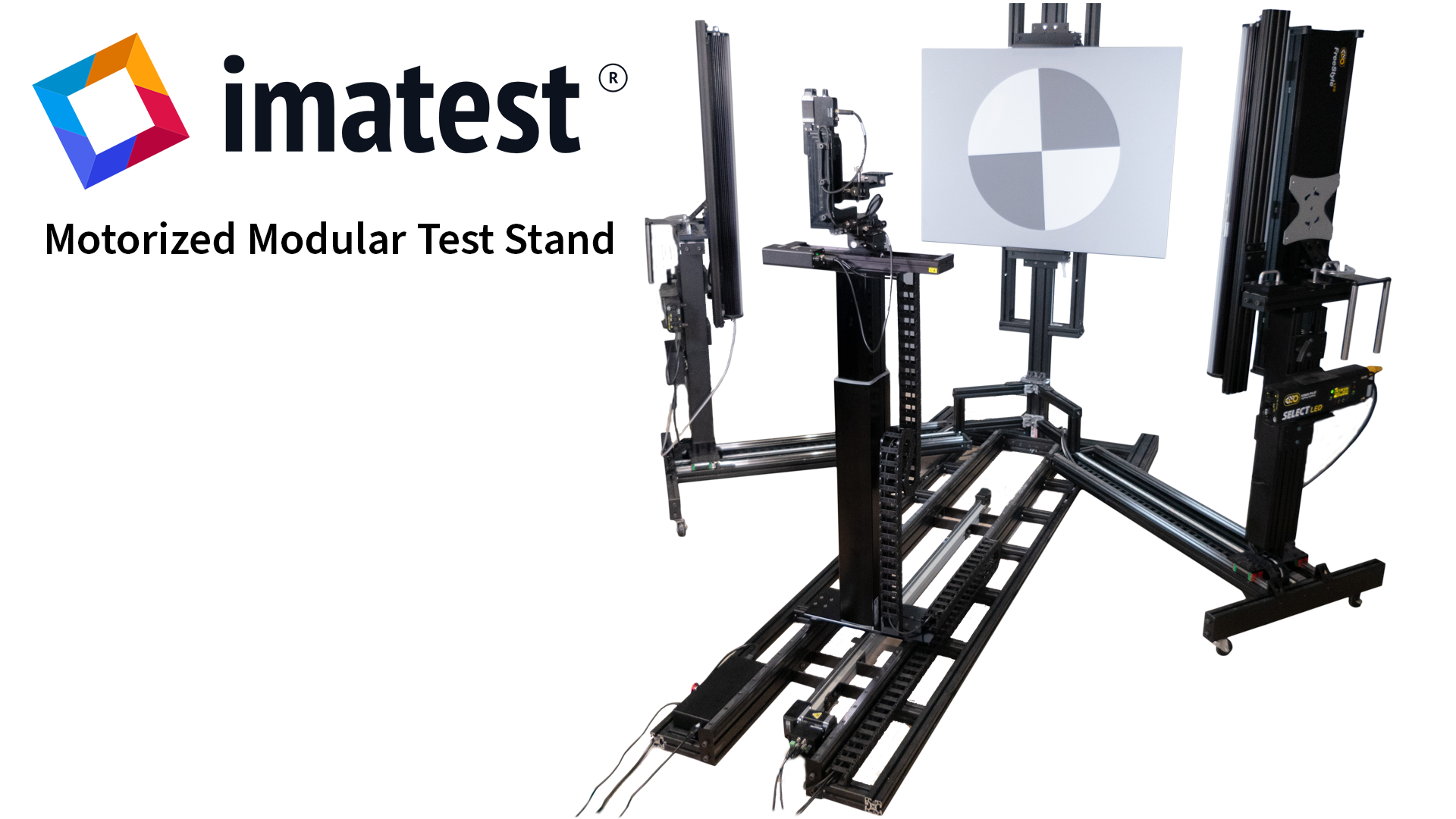

The motorization of each Modular Test Stand axis allows for automated positioning of your Camera. Create automated test plans with many camera-to-chart test distances. Perform live depth of field tests using computer controlled stages with precise linear motion . You can easily upgrade your existing Modular Test Stand. Imatest now offers the Z-Stage, lifting column, and fully motorized XYZ options, which can also be combined with the motorized Gimbal. The Imatest Control API allows for seamless control of all axes over a USB serial connection.

The Imatest Benchtop Test Stand (BTS) is an easy-to-use, modular platform for image quality testing. The fixture is well-suited for testing endoscopes. • Quickly test endoscopes and medical devices for sharpness, color accuracy, and more with an optional mount designed for endoscopes. • Derive objective metrics such as normalized stray light (flare) using images captured with the stray light module. • Perform long-range testing in a confined space using the target projector module.

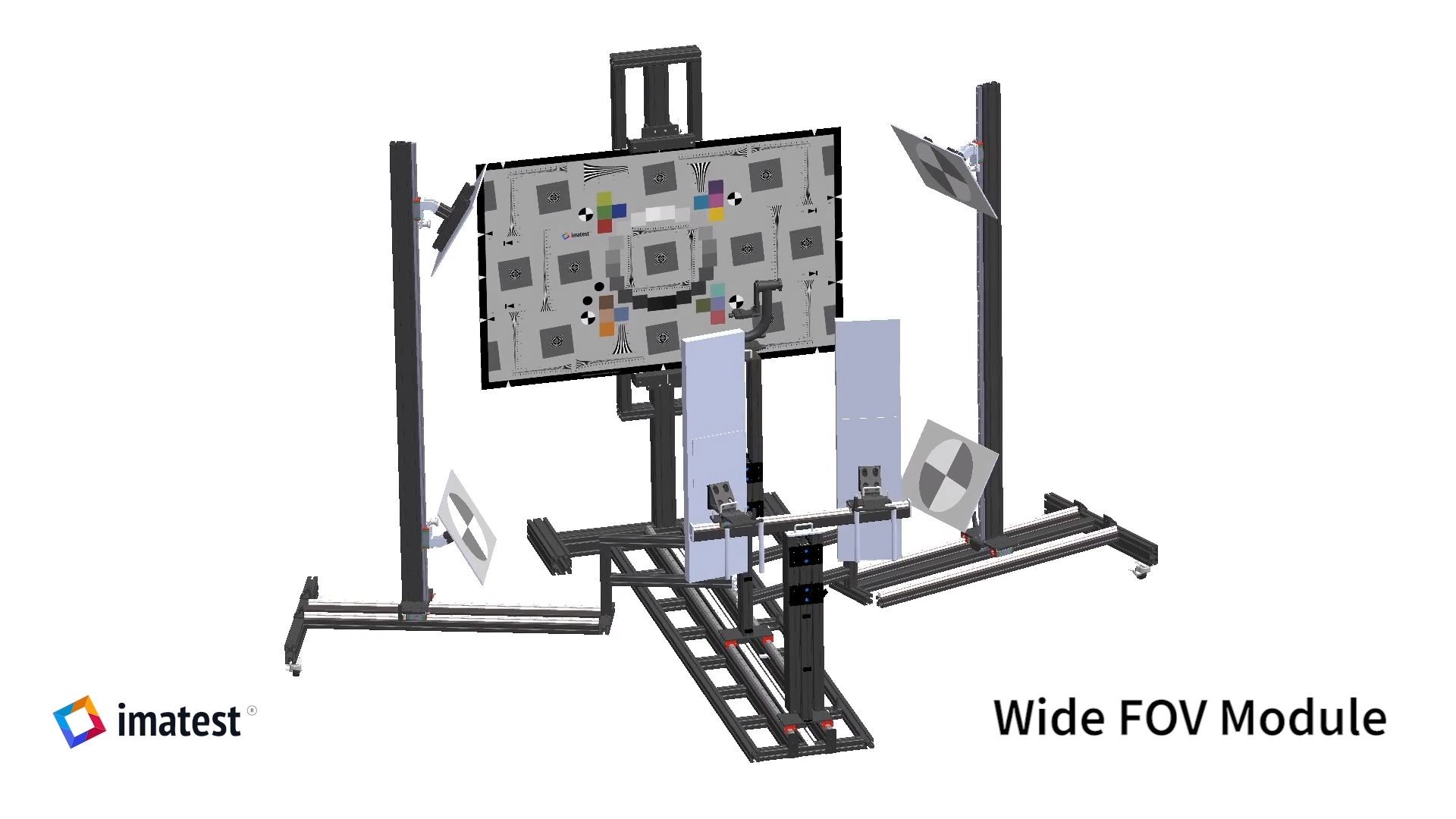

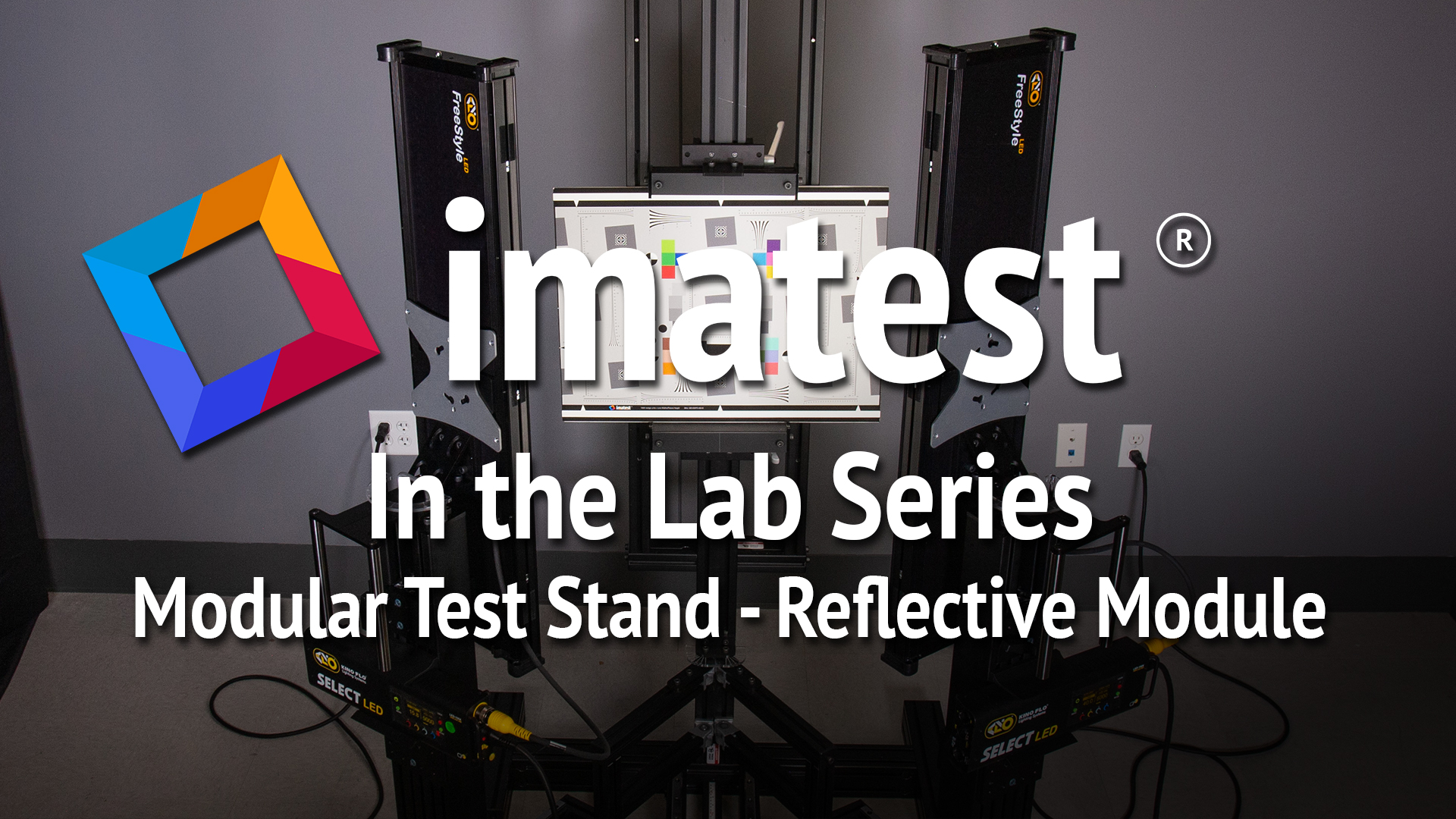

The Imatest Reflective Module is designed to work with Kino Flo Freestyle 31 lights and reflective charts. High-quality hardware allows you to effortlessly position lights, while angle and position markers indicate light bank locations for repeatable lighting configurations. The Imatest Wide Field of View (WFOV) Module provides an easy to use platform for testing sharpness of cameras with FOV up to 200 degrees.

Imatest 2020.2 has been sped up to the point where real-time focusing is possible.

A brief explanation is required. Broadly speaking, Imatest can analyze images from two types of source.

- image files in a great many formats, listed in Image file formats and acquisition devices,

- direct data acquisition from a variety of devices, listed in detail in Supported image acquisition hardware for Imatest Image Master.

Used by hundreds of companies for developing and testing digital cameras and imaging systems, Imatest Master allows users to test for a variety of image quality factors, including the ability to analyze over 30 test charts with different features for measuring color, tone, sharpness and more.

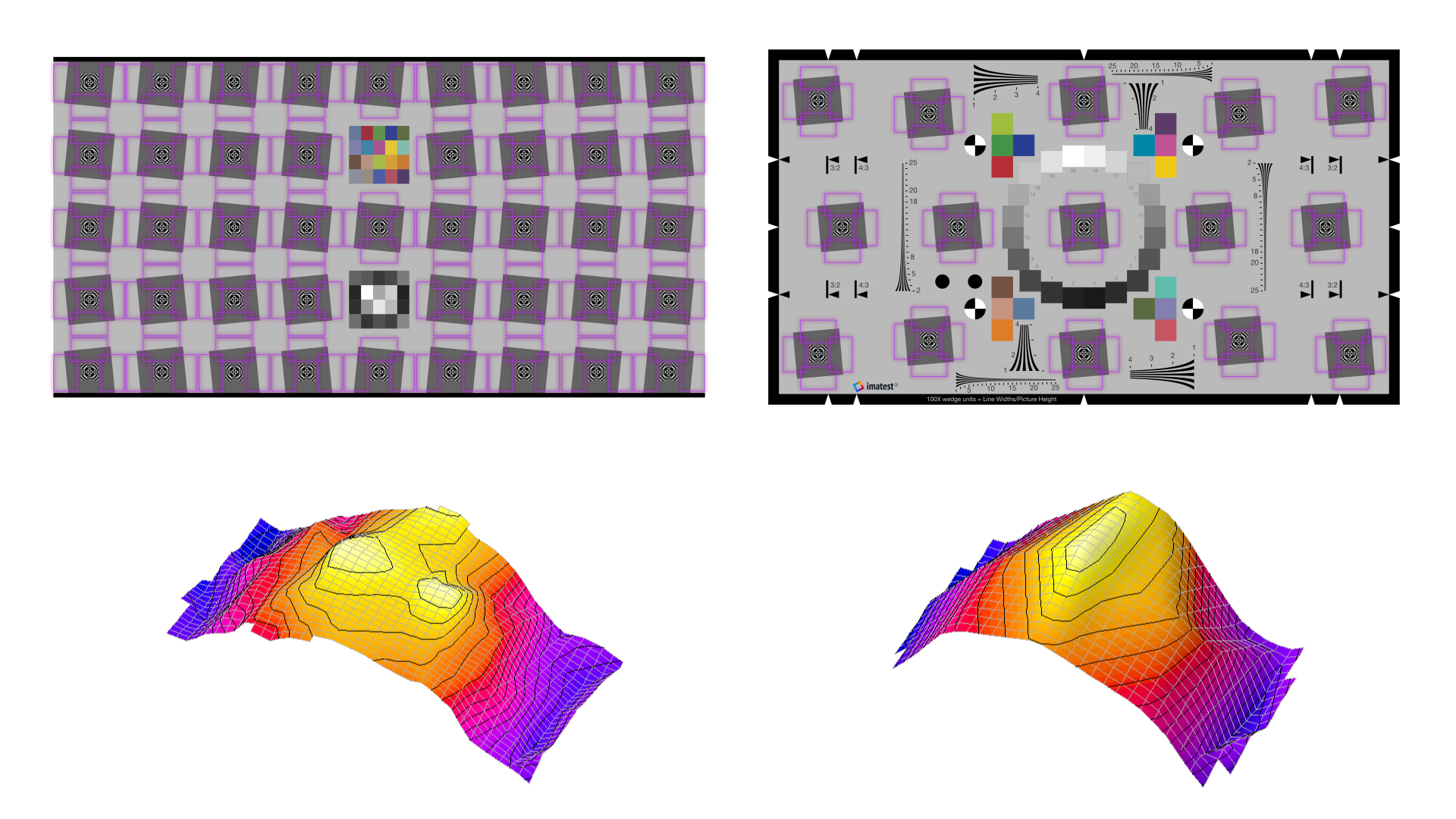

The key differences between SFRplus and eSFR ISO are outlined. These charts share many similar features and can be used to perform many similar image quality analyses. Understanding which features differ will help you select the most appropriate test chart to analyze your imaging systems.

The elements of the SFRplus test chart enable calculation of a number of image quality factors, including but not limited to spatial frequency response, geometric distortion, tilt, chromatic aberration, tonal response, gamma, white balance and color reproduction.

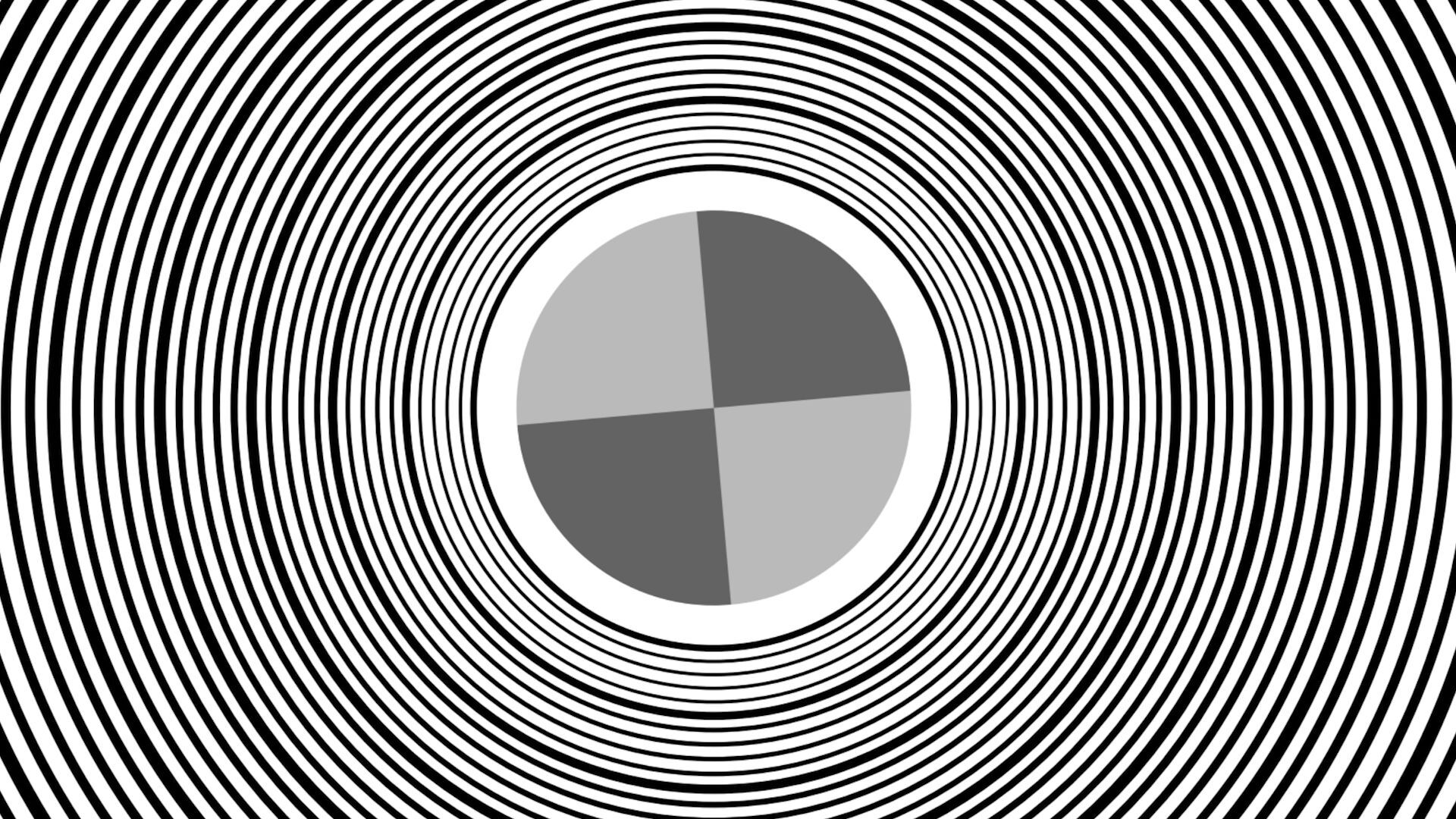

Imatest SFRreg performs highly automated measurements of sharpness and lateral chromatic aberration from images that contain registration mark patterns: circles with two light and two dark quadrants. Unlike standard test charts, these patterns do not need to be located on a flat surface.

Imatest can estimate an imaging system’s loss of resolution (point spread function) using a pair of collocated, near-sagittal and tangential slanted edges on SFRplus, eSFR ISO and SFRreg targets. Easily analyze and improve sharpness, chromatic aberration, and distortion measurements.

In the Lab

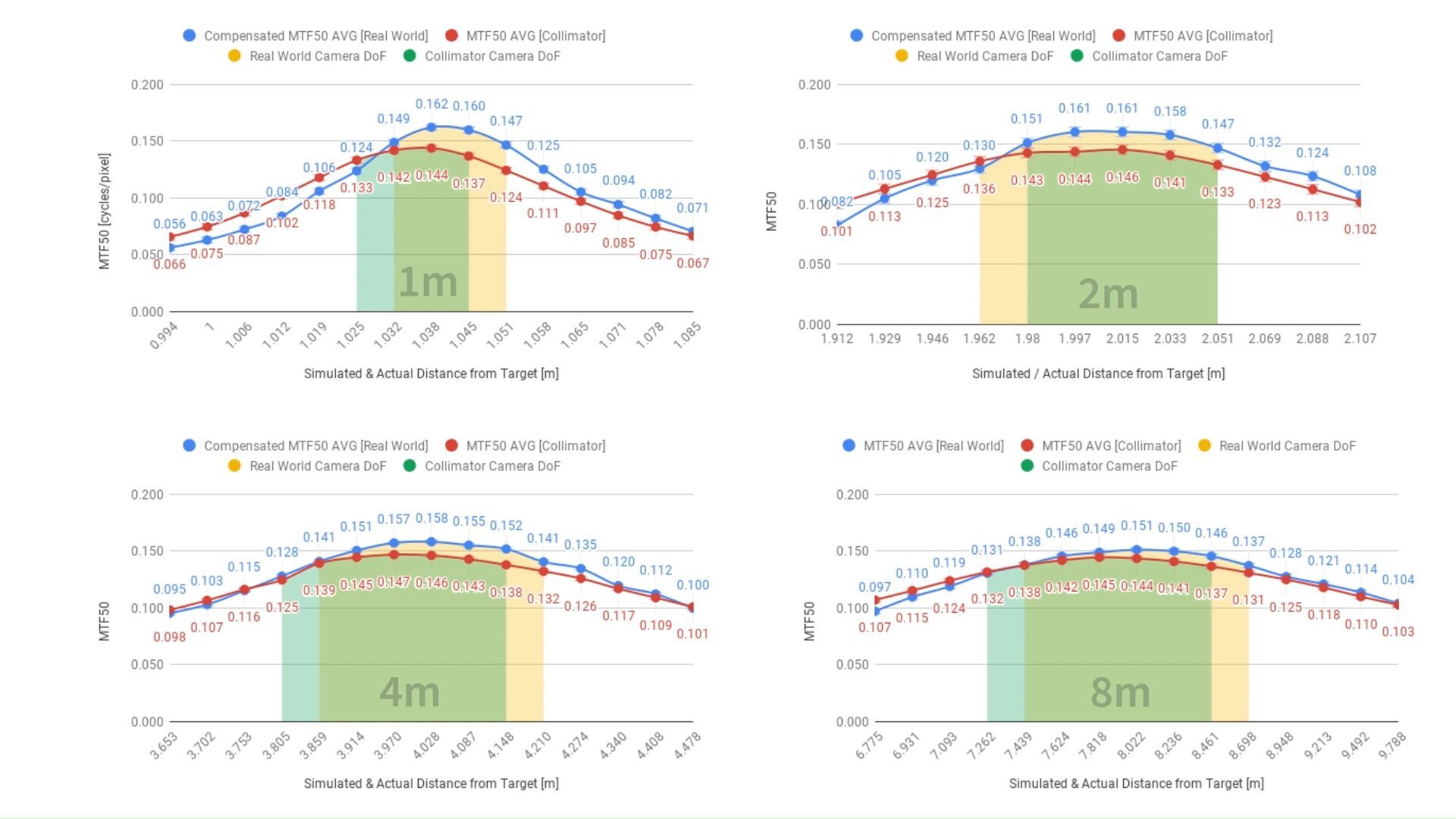

Understanding the performance of an imaging system at its operational working distance is crucial, but testing these systems at long distances isn’t always practical, especially in a production environment. Relay lenses can be used to effectively simulate longer test distances ranging from several meters to infinity. The Imatest Collimator Fixture (ICF) incorporates a relay lens and a test chart along with high precision motorized stages for automated positioning of your camera and target. To validate this lens formula and the fixture itself, we compare the MTF values from real-world images with those from the collimator fixture.

The WFOV Module is an add-on to Imatest’s Modular Test Stand and provides an easy-to use-platform for sharpness testing of wide FOV camera systems up to 200º. The fixture integrates with the Kino Flo LED Freestyle 31 lights. Here we walk you through how to implement this system in your lab setting. Learn More

Measuring and Reading IQ Plots

Webinars

Industry Events

Imatest attended Autosens Brussels where we demonstrated the BTS Stray light & Target Projector, and Norman Koren presented Information Capacity and related measurements (NEQ, SNRi and more), which are camera image quality metrics that hold strong promise of accurately predicting machine vision performance.

Imatest’s Norman Koren presents his vision for challenges in automotive image quality testing.

This video was previously recorded at Autosens Detroit 2017, the world’s leading vehicle perception conference. See more more at www.auto-sens.com.

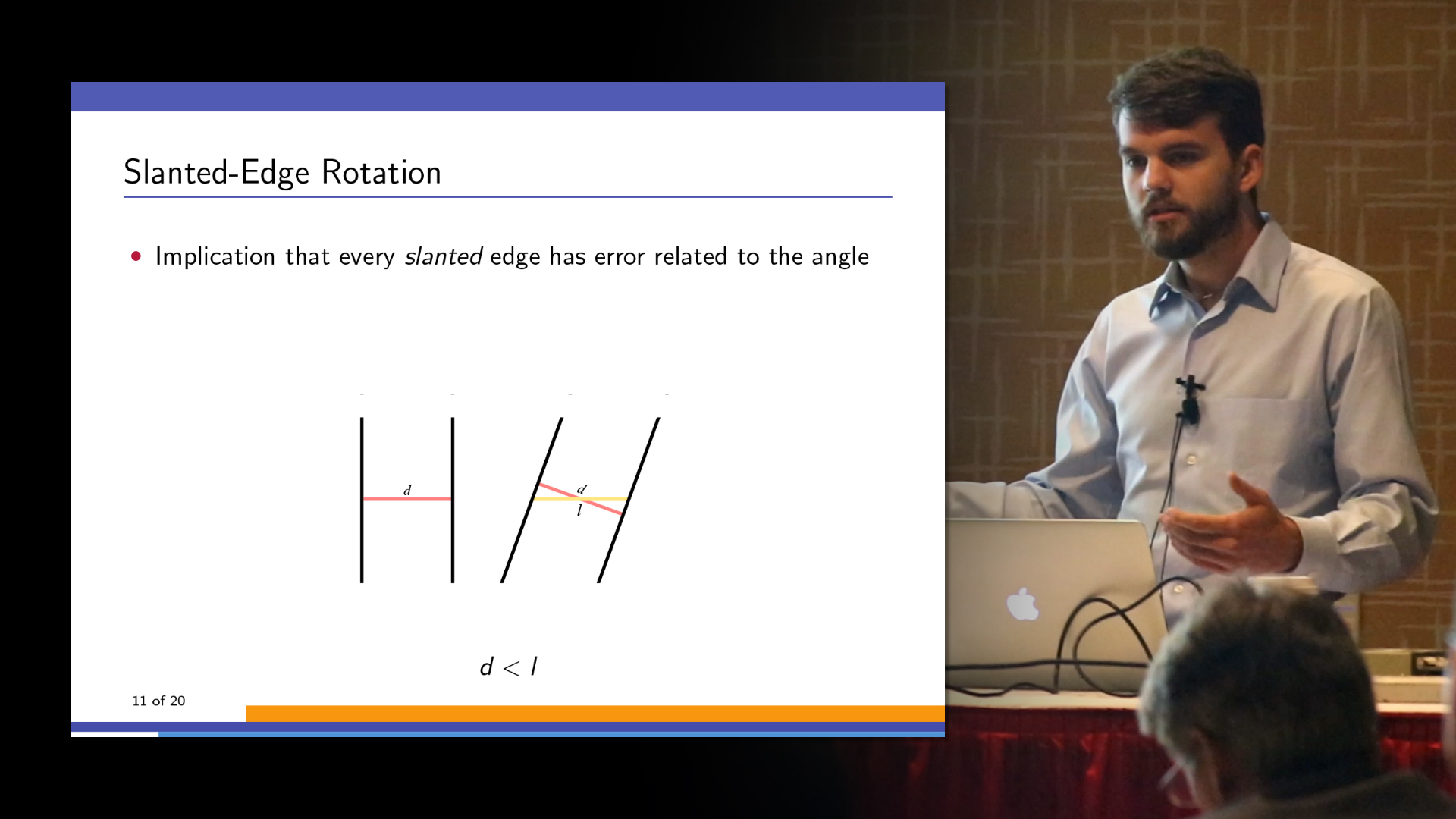

The slanted-edge method of measuring the spatial frequency response (SFR) as an approximation of the modulation transfer function (MTF) has become a well known and widely used image quality testing method over the last 10 years. This method has been adopted by multiple international standards including ISO and IEEE. Nearly every commercially available image quality testing software includes the slanted-edge method.

Standards

Speeding up videos

A Video Speed Controller is available on the chrome web store.

If you prefer to use the console, follow these steps for Google Chrome:

- Open the video.

- Hit ctrl+shift+I or right-click then choose Inspect to view the HTML for the web page. It will show up to the right of the video.

- Click on the Console tab.

- To increase the playback speed, for example by 1.5×, type “document.querySelector(‘video’).playbackRate = 1.5;” then press Enter.

- To return to normal speed, enter the same command with the playbackRate set to 1: “document.querySelector(‘video’).playbackRate = 1;”.

(You can copy and paste the text in steps 4 and 5.)